EVA edge bangding hot melt adhesives are based on Ethyl-Vinyl Acetate (EVA), for cabinet & furniture making. EVA edge banding glue manufacturer China, Iuclude: high, medium and low temperature edge bangding hot melt adhesive, eva glue for automatic and manual edge banding machines. High strength, environmentally friendly, easy to clean, good heat resistance, fast bonding, cost-effective EVA edge bangding hot melt adhesive.

Furniture industry grade EVA edge banding glue, can pass GB/T 18583-2008, ROHS, REACH, phthalate 17P, etc.

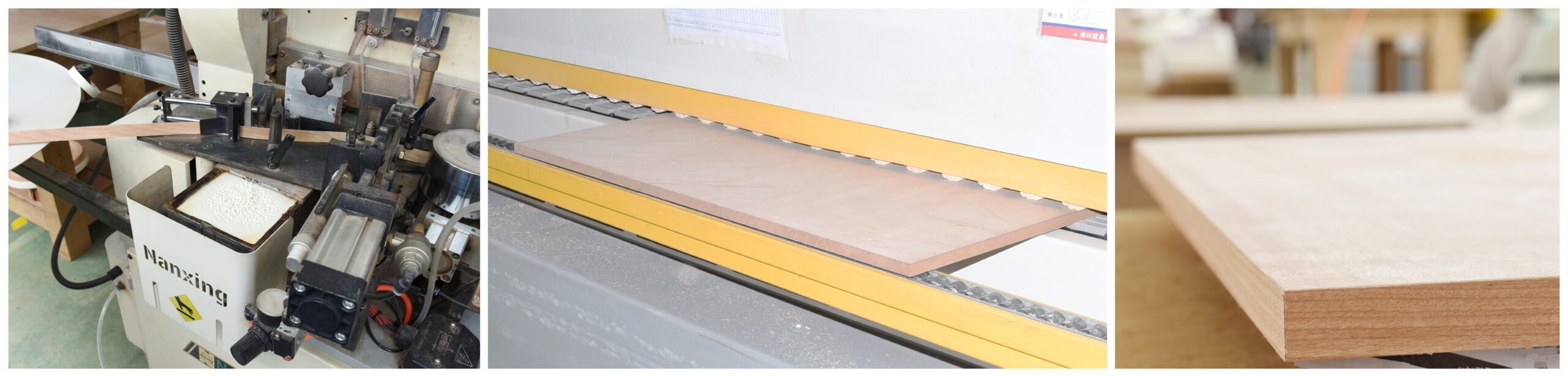

Application : EVA glue for PVC/ABS/wood veneer/paper edge banding tape. EVA adhesive for MDF/PB/HDF/plywood/acrylic boards, EVA adhesive compatible with Homag/Biesse/Brandt edge banding machines.

Provide: EVA edge banding hot melt adhesive customization, suitable for Wholesale EVA glue for modular furniture manufacturers, wholesale the best glue for edge banding.

Glue amount: 150-220 g/m² (The amount of glue applied depends on the density of the board).

| Color | Natural color,Yellow,White,Brown,Black |

|---|---|

| Gluing method | Machine gluing, Manual gluing |

Fast bonding, easy cleaning, environmentally friendly EVA edge banding adhesive

Good wetting, good heat resistance, high strength EVA glue for edge banding

PVC、ABS、Acrylic、Kraft paper、Non woven wood veneer、Solid wood veneer、Wood chips etc.

A1. EVA hot melt adhesive is a hot melt adhesive formed by copolymerization of ethylene and vinyl acetate under high pressure. Its characteristics are simple operation, manual operation, high cost-effectiveness, and certain tensile strength. PUR hot melt adhesive is a reactive polyurethane hot melt adhesive, characterized by high production process requirements, small adhesive lines, good moisture resistance, and higher tensile strength than EVA hot melt adhesive.

A2.a. The operating environment temperature is too high or too low. b. The amount of glue applied is too low. c. The moisture content of the board is too high. d. The board or edge bangding material contains grease, which prevents the glue from penetrating.

A3.a. The temperature setting of the edge banding machine is too low. b. The amount of glue applied is too large. c. There is direct air blowing directly towards the glue coating shaft. d. The selected adhesive has too high viscosity.

A4. a. The amount of glue applied is too large. b. The cleaning module of the edge banding machine is damaged. c. The sol temperature of the edge banding machine is set too high.

A5.a. The heating time of hot melt adhesive in the glue pot is too long. b. The thermal sensing device of the edge banding machine is damaged, resulting in consistently high temperatures and carbonization of the adhesive. c. Hot melt adhesive is stored for too long, and the adhesive undergoes oxidation reaction.

A6. a. Insufficient glue application. b. The temperature of the board or edge banding is too low. c. The conveyor belt speed of the edge banding machine is set too low. d. The pressure of the edge banding machine is too low.

A7. a. The roller pressure of the edge banding machine is too low. b. The edge banding board is too long and the front end is subjected to uneven force. c. The initial adhesive strength of the selected hot melt adhesive is too low.

A8.a. The glue is contaminated with dust at the hot melt glue pot. b. There is rubber on the surface of the coated shaft. c. The processing accuracy of the board is insufficient.

A9.According to the use temperature, it is divided into low temperature/medium temperature/high temperature EVA edge banding hot melt adhesive; according to the degree of automation, it is divided into manual/semi-automatic/fully automatic edge banding machine EVA edge banding hot melt adhesive; according to the edge banding material, it is divided into PVC/ABS/PET/veneer/paper EVA edge banding hot melt adhesive; according to the board material, it is divided into MDF/PB/HDF/solid wood/acrylic board EVA edge banding hot melt adhesive; according to the purpose, it is divided into cabinet/wardrobe/door EVA edge banding hot melt adhesive.

As one of the best EVA hot melt adhesive suppliers, manufacturers, exporters, factories, companies and wholesalers in China, Blue Rhino Adhesives supplies EVA adhesive for edge banding machines. We can meet customers’ special requirements and send samples for free. So, to buy or purchase EVA glue for woodworking machinery, you can choose Zhongshan Blue Rhino New Materials Co., Ltd.

Zhongshan Blue Rhino Adhesive Co., Ltd. is an OEM EVA hot melt adhesive factory in China. With its strong production capacity of EVA edge banding hot melt adhesive, it can provide OEM services based on the purchasing needs of furniture factories and traders around the world.

1、With 20 years of experience in adhesive research and development, well-known EVA edge banding hot melt adhesive supplier in China,our technical engineers have a thorough understanding of bonding substrates and gluing processes, greatly improving your production efficiency.

2、In order to ensure the stable quality of the adhesive, all raw materials used come from international chemical giants, such as: LG Chem, Celanese, Dow Chemical, BASF, Sinopec

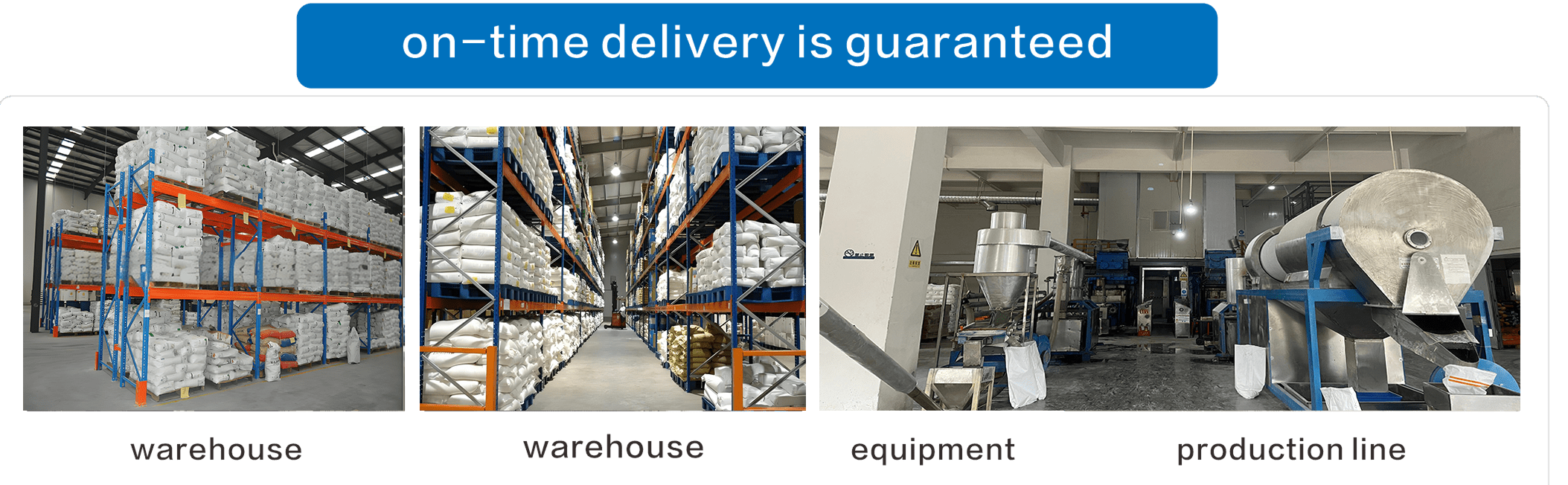

3、18 fully automatic intelligent glue production lines, well-known EVA edge banding hot melt adhesive manufacturer in China,with an annual output of more than 50,000 tons, and sufficient inventory to ensure that goods reach customers on time.

4、Our EVA edge banding hot melt adhesive have SGS, VOC, ROHS, ISO9001 and other test reports to ensure that the glue is safe and environmentally friendly.

5、We have many years of experience in international logistics and transportation, and are familiar with sea shipping, land transportation, air transportation and other methods, so you don’t have to worry about glue transportation.

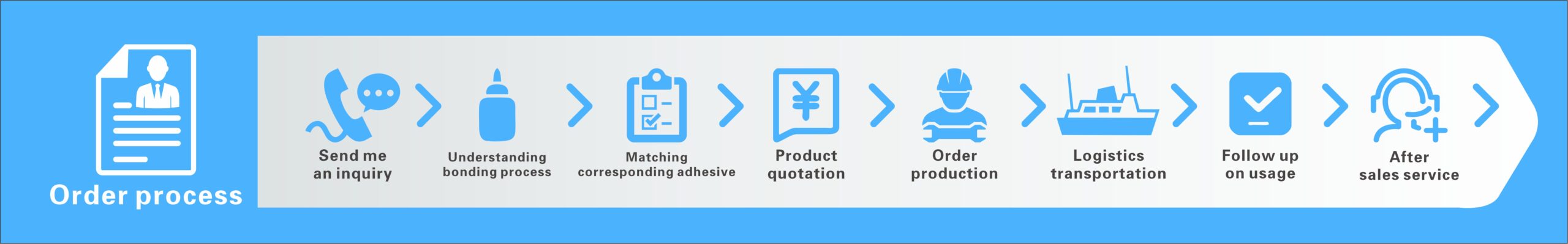

Receive your message, we will contact you within 1 working day, please pay attention to the email with the suffix —“sales@bluerhino-adhesive.com”.

A factory with more than 10 years of adhesive experience will answer your questions

Mobile / WhatsApp / WeChat:

+86 137 0239 0495

Email: sales@bluerhino-adhesive.com

We will contact you within 1 working day, please pay attention to the email with the suffix —“sales@bluerhino-adhesive.com”.