Wood splicing glue is an adhesive used to glue the edges of multiple pieces of wood together to form a larger piece of wood. Furniture manufacturers choose wood splicing instead of raw wood, mainly because raw wood is expensive and easy to deform. As a Chinese manufacturer with more than 10 years of experience in the production and application of wood splicing glue, the following will share with furniture manufacturers and glue traders how to choose wood splicing glue from multiple perspectives:

What is wood splicing glue

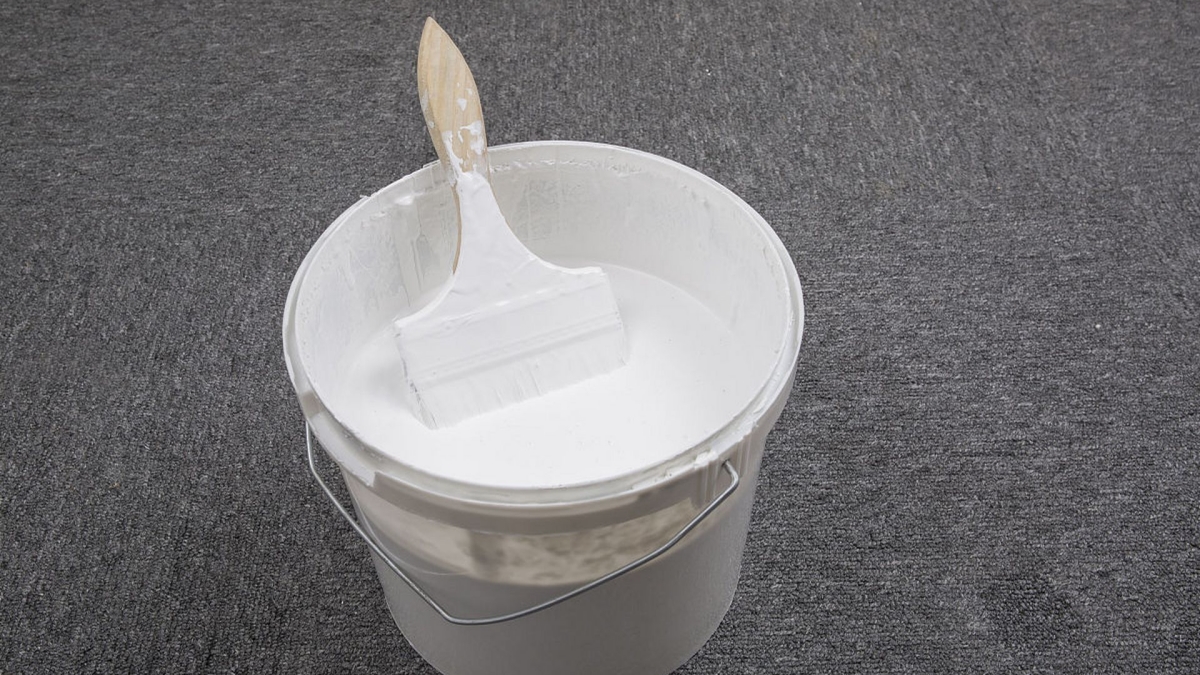

Wood splicing glue is made of polyvinyl acetate emulsion, called PVA glue, and is white in color, but some customers will require the addition of corresponding pigments to adjust to the color of the wood. Wood splicing glue is used to glue the edges of multiple pieces of wood together to form a whole flat board. When used in furniture factories, it can be cut into the required size. Wood splicing glue plays an extremely important role in the production of wooden products. It is widely used in furniture, wooden floors, wooden doors, speakers, handicrafts, wooden toys, billiard tables, DIY handmade products, etc.

What are the advantages of wood splicing adhesive

Strong adhesion

As a water-based adhesive, wood splicing glue can penetrate into the gaps of wood very well, and can form excellent adhesion after the glue dries. When the wood is subjected to a large tensile force, it does not start to break from the edge bonding, which is the standard for judging the strength of the glue adhesion.

Safety and environmental protection

As consumers pay more and more attention to the safety and environmental protection of products, glue manufacturers choose wood splicing glue formulas with low volatile organic compounds to reduce the impact of glue on human health and the environment. Compared with other solvent-based adhesives, water-based wood splicing glue is safer and more environmentally friendly.

Wide adaptability

Wood splicing glue is suitable for bonding most types of wood on the market, such as particleboard, medium-density fiberboard, high- and low-density solid wood, etc. In terms of operation technology, it is suitable for manual and machine bonding.

Simple operation

The user only needs to apply the wood splicing glue evenly on the wood surface with a brush or roller, and then use a clamp to fix it and press it for a certain period to complete the entire bonding process.

Water resistance

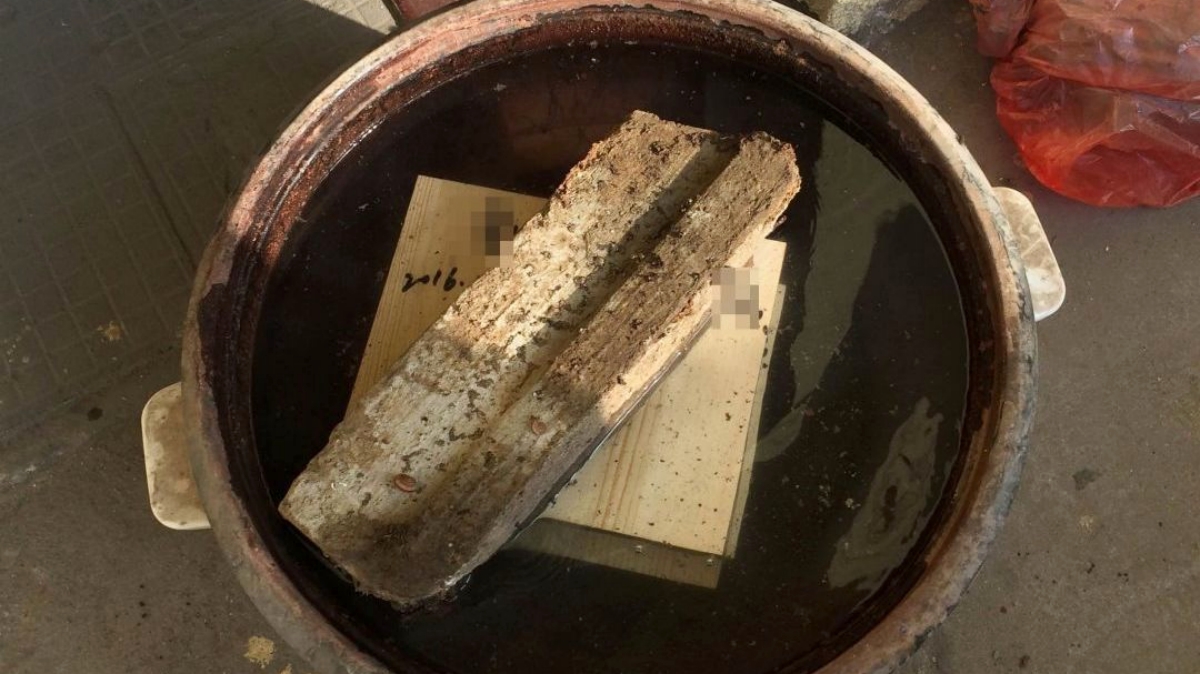

Considering that some wooden products will need to be used in high-humidity environments in the future, it is an important indicator that the glue can maintain the bonding effect in a humid environment. The wood splicing glue is mixed and stirred with a curing agent to make the glue have a certain degree of water resistance.

Is wood splicing glue waterproof

Yes, wood splicing glue has a certain degree of water resistance. The wood splicing glue and curing agent are mixed in a ratio of 100:15, which can make the spliced wood soak in 100°C water for 4 hours without cracking. Water resistance is a key factor in judging whether the wood splicing glue is good or not. After all, the environment in which the wood is located may have high humidity.

What are the precautions for using wood splicing glue

Wood moisture content

The moisture content of wood is the percentage of the weight of the water contained in the wood to the weight of the wood after drying. The moisture content of wood is closely related to the splicing effect of the boards. If the moisture content is too high, the glue will not be able to penetrate between the boards. If the moisture content is too low, the glue will be completely absorbed into the wood, resulting in no glue at the edge of the board and no bonding effect. The best moisture content of wood is 8-12%. You can use a moisture tester to test it before bonding the wood.

Apply glue evenly

When bonding wood, you need to ensure that the wood splicing glue is evenly applied to the wood surface. Do not allow for a partial lack of glue, which can easily lead to cracks at the edges of the wood.

Open time

The open time of board splicing glue refers to the time after the glue is applied to the board and the glue still has a bonding effect. The open time of glue is affected by temperature and humidity. The lower the ambient temperature and the higher the humidity, the longer the open time will be. Depending on the ambient temperature and humidity of the construction site, the reasonable open time for board splicing glue is within 10-15 minutes.

Ratio and usage time

When the board splicing glue is mixed with the curing agent, the optimal ratio of glue to curing agent is between 100:10-15. Adding too much curing agent will make the glue brittle and affect the bonding performance. Adding too little curing agent will slow down the curing time of the glue and deteriorate the water resistance.

The wood splicing glue mixed with the curing agent should be used within 60 minutes. If it is used to bond wood after the time is exceeded, the bonding performance of the glue will be affected.

Balanced pressure

Using a clamp to pressurize the wood coated with glue is to allow the glue to penetrate the wood better. Therefore, it is necessary to ensure that the clamp applies pressure to the wood evenly to avoid situations where there is no pressure in some parts. Especially at the ends of the wood, if the pressure is not enough, it is easy to crack.

In summary, the precautions for using wood splicing glue include wood moisture content, apply glue evenly, open time, ratio and use time, balanced pressure, etc. When carpenters perform wood splicing, if these precautions can be taken, cracking of the wood after splicing can be avoided.

How to choose wood splicing glue

After talking about the precautions for using wood splicing glue, let’s share a few key points on how to choose wood splicing glue:

Wood type

Different wood types have different corresponding pore porosity. The pore porosity of wood is related to the penetration effect of glue. Therefore, before choosing wood splicing glue, first understand the type of wood and then choose the appropriate glue. Common wood types include particle board, MDF, high and low-density solid wood, etc.

Gluing method

There are two ways to apply glue for wood splicing glue: manual gluing and machine gluing. The viscosity of the glue will affect the effect of gluing. For example, glue with too high viscosity is not conducive to manual gluing. Therefore, after confirming the gluing method, it is necessary to communicate with the wood splicing glue supplier about the viscosity to facilitate the actual use of production.

Water resistance

If the wood to be joined needs to be water resistant, it is important to ensure that the glue can be mixed with the curing agent.

Application experience

The glue supplier’s wood bonding application experience is related to the success rate of glue and wood matching. When consumers buy wood splicing glue, it is recommended to choose a glue supplier with many years of R&D and production experience.

Price

The price of wood splicing glue is related to the final cost of wood products. Choosing a big brand glue supplier can not only provide low product prices but also ensure the stability of glue, thereby reducing the probability of quality problems in the production process.

In summary, when you choose wood splicing glue, the key factors to consider are wood type, glue method, water resistance, application experience, price, etc. Blue Rhino Adhesives is a Chinese woodworking glue supplier with more than 10 years of experience in the production and application of wood splicing glue. If you have any questions about the selection and use of wood splicing glue, you can consult us and we will answer you immediately.