Yes, the majority of hot melt adhesive manufacturers offer sample services, especially for edge banding applications. Since edge banding hot melt adhesives are predominantly used by large-scale commercial furniture manufacturers, offering samples for testing is a standard practice in industrial procurement. Trusted suppliers of edge banding hot melt adhesives not only provide samples but also offer professional technical support to ensure optimal product performance.

In this article, we will explain the complete sample acquisition process, key considerations, and expert advice to help you make an informed decision.

Can I Request Samples of Edge Banding Hot Melt Adhesives from the Manufacturer?

Yes, it is highly recommended that you request samples directly from the manufacturer for testing. Most hot melt adhesive manufacturers globally offer samples of EVA, PUR, and PO edge banding hot melt adhesives. While these samples are typically provided free of charge, it’s important to note that international shipping costs are generally the responsibility of the buyer. This is a standard practice in the industry.

Why Do Edge Banding Hot Melt Adhesive Suppliers Offer Samples?

- Industry Standard: Providing samples for testing before making chemical material transactions is a common international practice.

- Building Trust: Offering samples allows suppliers to directly demonstrate the quality and technical capabilities of their products.

- Technical Compatibility: Samples help both parties assess whether the product meets the specific requirements of your edge banding equipment, board type, and operating environment.

- Minimizing Future Issues: Pre-testing for compatibility reduces the risk of quality disputes after bulk purchases, ensuring a smoother transaction.

For these reasons, edge banding hot melt adhesive suppliers are eager to provide samples to buyers. This practice not only facilitates product sales but also helps build trust, showcase technical expertise, and prevent future complaints.

What to Test in Edge Banding Hot Melt Adhesive Samples?

Before purchasing edge banding hot melt adhesive in bulk, sample testing is a crucial step to ensure the desired outcome. If furniture manufacturers or hot melt adhesive traders purchase large quantities without testing, they may encounter issues like poor adhesion, excessive stringing, and thick glue lines during production. These problems can lead to significant and irreversible losses. Therefore, it’s essential to conduct the following tests on samples:

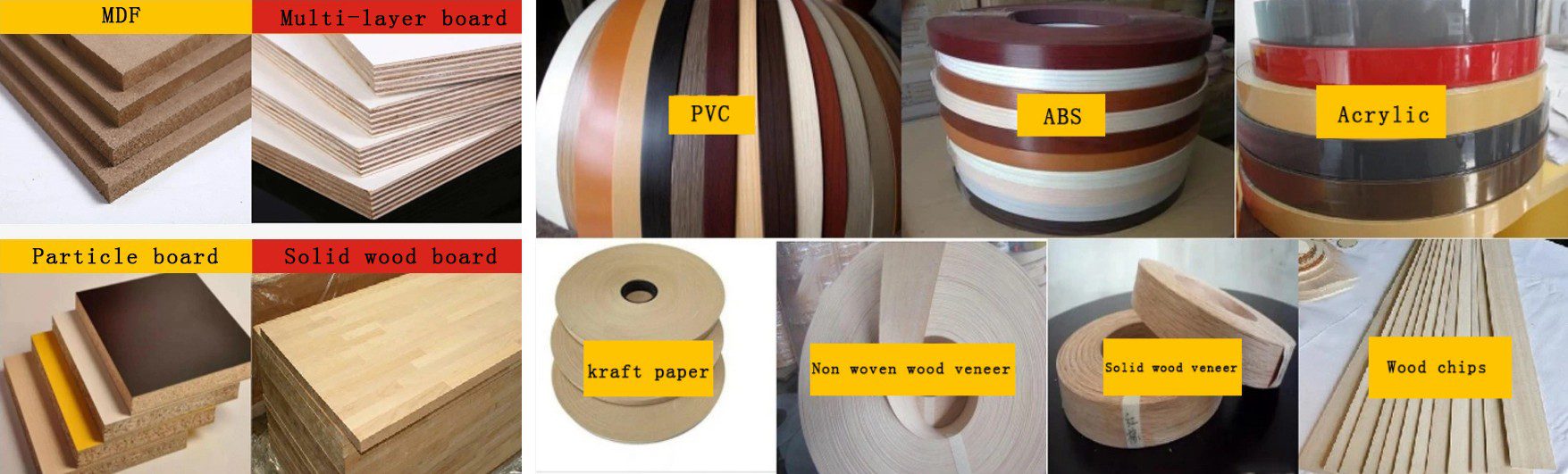

1. Compatibility of the Hot Melt Adhesive with the Edge Banding Material

Common edge banding materials include PVC, ABS, PP, PET, melamine, acrylic, wood, and more. Similarly, board types like particleboard, medium-density fiberboard (MDF), plywood, solid wood, acrylic, melamine, and fire-resistant boards all require different adhesive characteristics. The thickness and width of the edge banding material can also impact the test results. Each material may require specific viscosity, penetration, and strength from the adhesive. Sample testing is crucial to quickly assess compatibility with the edge banding material.

2. Compatibility with the Edge Banding Machine

The performance of edge banding machines—whether manual, semi-automatic, fully automatic, or ultra-high-speed machines—affects the edge banding results. Factors such as melting speed, fluidity, open time, and application method can all influence the final edge banding quality. Therefore, it is essential to test the adhesive’s performance with the specific machine to ensure compatibility.

3.Performance Testing of the Hot Melt Adhesive

The overall performance of the hot melt adhesive directly impacts the final edge banding results. Key characteristics to test include odor, transparency, tensile strength, temperature resistance, fluidity, chemical resistance, water resistance, and the amount of adhesive required for application.

How to Request Edge Banding Hot Melt Adhesive Samples from the Manufacturer?

Requesting samples from manufacturers is typically straightforward, but it’s important to provide detailed information so that the manufacturer can recommend the most suitable samples. Here’s the information you should include in your sample request:

- Edge Banding Machine Type and Operating Speed (manual, semi-automatic, automatic, etc.)

- Edge Banding Material Type (PVC, ABS, PP, melamine, acrylic, etc.)

- Edge Banding Thickness

- Panel Type and Width (high-density fiberboard, particleboard, plywood, solid wood, fire-resistant board, etc.)

- Hot Melt Adhesive Color and Performance Requirements (colors include natural, yellow, white, brown, etc.; performance includes tensile strength, temperature resistance, water resistance, etc.)

- Preferred Shipping Method (DHL, UPS, FedEx, Aramex, sea freight, etc.)

Are Samples of Edge Banding Hot Melt Adhesive Free?

No, Small sample quantities (500-1000g) are typically provided free of charge. However, international shipping costs are generally the responsibility of the buyer, which is a standard industry practice. If multiple types of samples are required, or if the samples are large or need special customization, the manufacturer may charge a sample fee. Buyers can often negotiate with the manufacturer to have the sample fee refunded after placing a regular order; most manufacturers are open to this arrangement.

Frequently Asked Questions

Q: If the sample test is unsuccessful, can I receive adjusted samples?

A: Yes, the manufacturer will adjust the formula or recommend alternative products based on your feedback to better meet your needs.

Q: After I’m satisfied with the samples, what is the minimum order quantity?

A: The minimum order quantity (MOQ) for hot melt adhesive typically ranges from 200kg to 500kg, depending on the product. This MOQ is often based on the cost-effectiveness of shipping.

Q: How can I ensure the bulk order quality is consistent with the samples?

A: Choose a hot melt adhesive supplier that offers a “sample and bulk order consistency guarantee.” Keep the approved sample as the acceptance criterion to ensure consistency.

Q: If I don’t make a purchase immediately after testing the samples, will it affect future cooperation?

A: No, professional suppliers understand the customer’s purchasing cycle. As long as there is honest communication, normal purchasing timelines will not affect future cooperation.

Conclusion:

Yes, you can definitely obtain edge banding hot melt adhesive samples from the manufacturer, and it is highly recommended. Whether you are a furniture manufacturer, edge banding supplier, woodworking equipment provider, or international distributor, requesting hot melt adhesive samples is the first crucial step to ensuring the success of your project. As one of the leading edge banding hot melt adhesive manufacturers in China, Blue Rhino Adhesives invites all buyers to request free samples from us.