Buy hot melt glue for EPE foam, our EVA-based hot melt adhesive for EPE foam is specially formulated for strong and flexible bonding in a wide range of foam applications. Designed for high-efficiency lamination and packaging processes, this adhesive delivers excellent adhesion, clean melt behavior, and minimal odor, making it ideal for automated production lines.

As a manufacturer of EPE foam hot melt adhesive, the formula of hot melt adhesive is optimized according to the low surface energy, porosity, flexibility and other characteristics of EPE foam, so that the glue has excellent wettability and permeability in the molten state, does not harm the foam, and can form a high-strength flexible adhesive layer after cooling and curing.

Application range: EPE foam bonding itself and bonding with other materials (cardboard, kraft paper, wood, metal foil, plastic, etc.), suitable for roller, nozzle, or manual application.

Application areas: Industrial EPE Foam hot melt for packaging industry, automotive interior, construction and furniture, sporting goods, handmade DIY, handicrafts, etc.

Features: Low-temperature EPE foam adhesive, Non-corrosive EPE foam adhesive, Fast-curing EPE foam adhesive.

Environmental requirements: 10-30℃ is the best. The ambient temperature will affect the speed of curing.

| Color | Transparent, white, yellow |

|---|---|

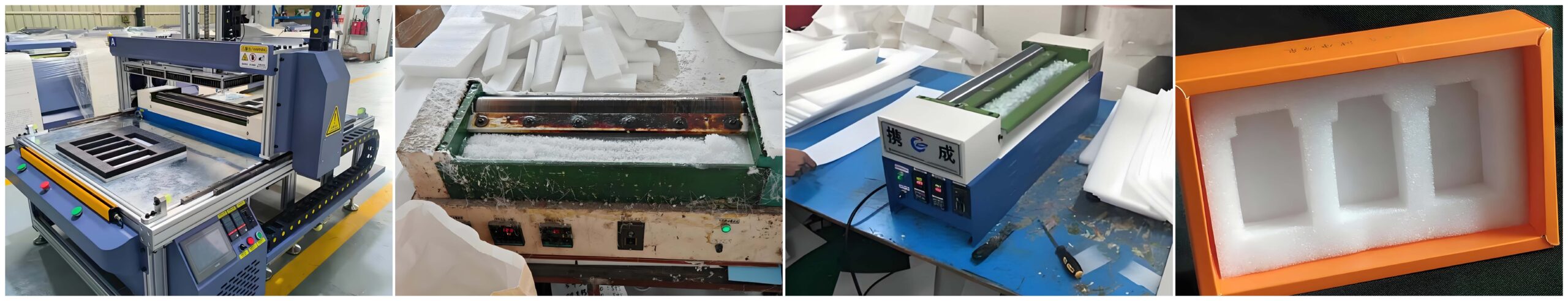

| Gluing method | Machine gluing, Manual gluing |

Excellent filling and permeability, good film flexibility

Anti-yellowing, no drawing, excellent weather resistance

EPE foam has poor temperature resistance (typically no more than 80°C) and is prone to shrinkage, melting, or deformation at high temperatures. The key to using hot melt adhesive without damaging EPE foam is to carefully consider the following key points: adhesive type, application temperature, and application method.

Adhesive type: Low-temperature EVA hot melt adhesive with a low softening point (approximately 110-130°C), quick drying, and solvent-free.

Application temperature: The hot melt glue gun temperature setting is recommended to be 110-130°C.

Application method: Ensure uniform flow, avoiding prolonged application of heat to the same point. Apply the adhesive immediately after application, completing the bond within 5-10 seconds. Apply light pressure to avoid damaging the foam structure.

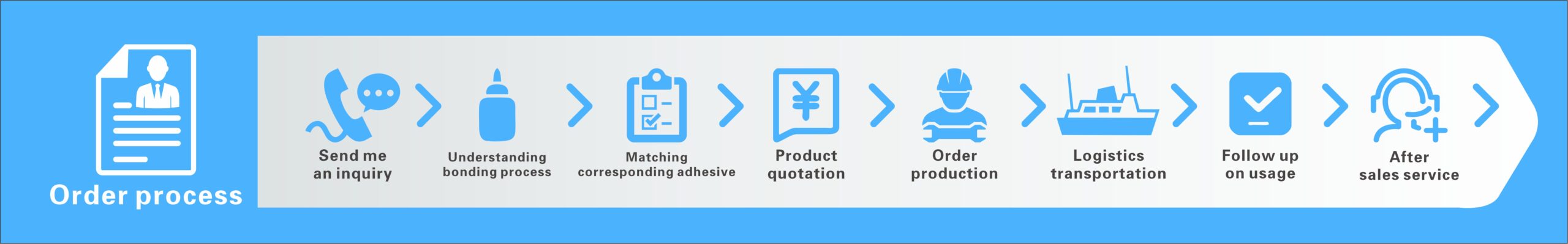

Zhongshan Blue Rhino New Materials Co., Ltd. is a Chinese manufacturer, supplier, and exporter of EPE foam hot melt adhesive. Our products are available in both roller coating and spray coating lines. We support OEM, bulk purchase, and custom EPE foam hot melt adhesives.

1. With 20 years of experience in adhesive research and development, well-known EPE foam hot melt adhesive suppliers in China, our technical engineers have a thorough understanding of bonding substrates and gluing processes, greatly improving your production efficiency.

2. In order to ensure the stable quality of the adhesive, all raw materials used come from international chemical giants, such as: LG Chem, Celanese, Dow Chemical, BASF, Sinopec

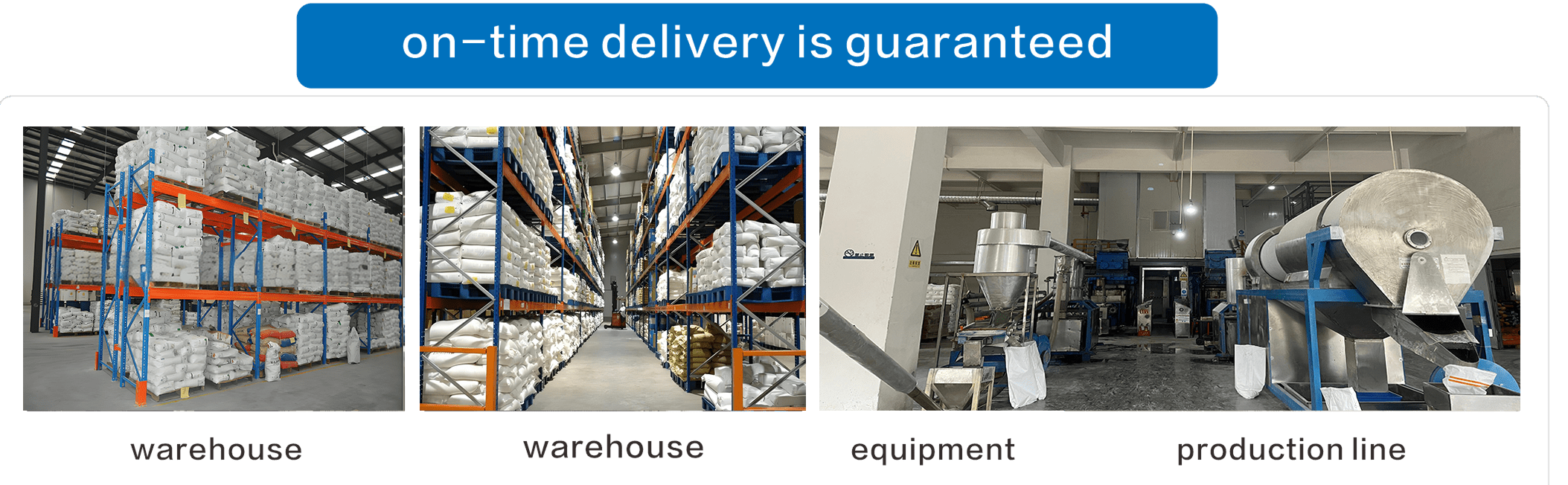

3. 18 fully automatic intelligent glue production lines, well-known EPE foam hot melt adhesive manufacturers in China, with an annual output of more than 50,000 tons, and sufficient inventory to ensure that goods reach customers on time.

4. Our EPE foam hot melt adhesive have SGS, VOC, ROHS, ISO9001 and other test reports to ensure that the glue is safe and environmentally friendly.

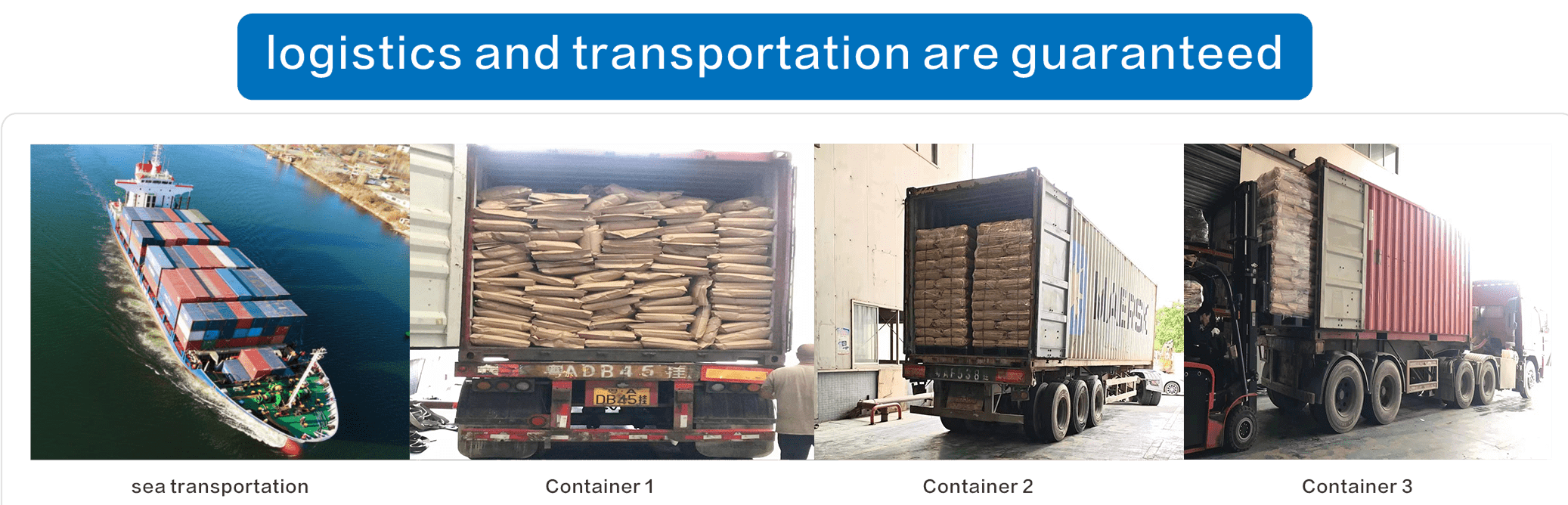

5. We have many years of experience in international logistics and transportation, and are familiar with sea shipping, land transportation, air transportation and other methods, so you don’t have to worry about glue transportation.

Receive your message, we will contact you within 1 working day, please pay attention to the email with the suffix —“sales@bluerhino-adhesive.com”.

A factory with more than 10 years of adhesive experience will answer your questions

Mobile / WhatsApp / WeChat:

+86 137 0239 0495

Email: sales@bluerhino-adhesive.com

We will contact you within 1 working day, please pay attention to the email with the suffix —“sales@bluerhino-adhesive.com”.